50 YEARS OF EXPERIENCE AT YOUR SERVICE

A leader Italian company in the professional cleaning market

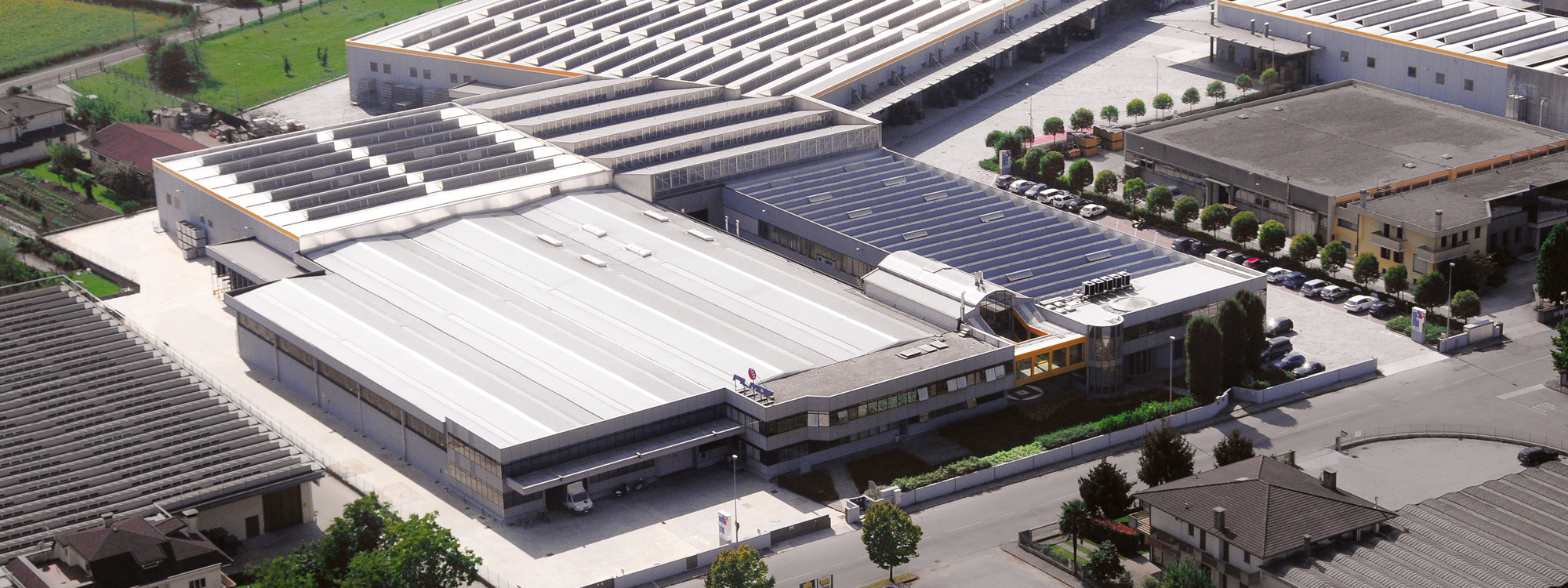

Filmop was founded in the early 70s as a company specialized in the manufacturing of manual cleaning equipment for professional use.

Located in the main production areas in the North East of Italy, it is a leading company in the professional cleaning market and a reliable partner for thousands of professional people who operate in this field, proud to develop the “Made in Italy” trademark all over the world.

Today Filmop International exports to over 80 countries worldwide with the maximum speed, reliability and efficiency.

Mission

Filmop International has always been inspired by the following main principles, that are surely behind its growth and development:

- an important spur to innovation and research

- a constant attention towards customer’s satisfaction

- unequalled production flexibility

- a considerable quick order processing with very fast and on time deliveries

Filmop International primary goal is to design and create the best cleaning systems to meet all the different needs in the market, placing at the centre of any new project the wellbeing and health of people in the full respect for the environment.

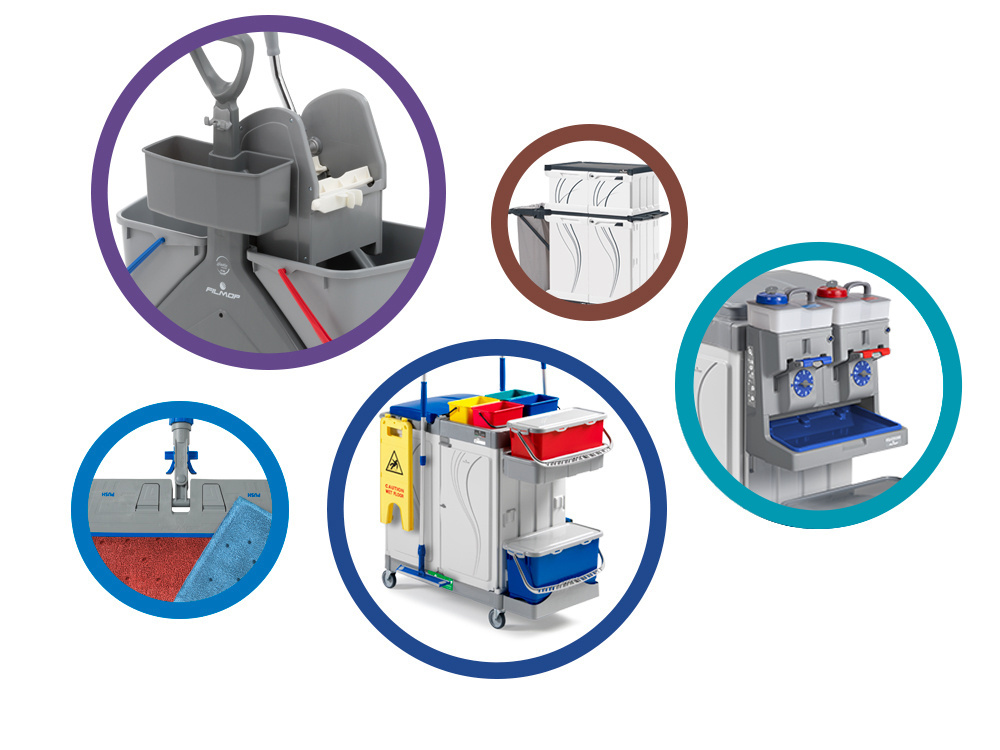

A successful range of products

During the last 30 years Filmop has played a main role in the process of change that has affected professional cleaning.

In particular it has been the first Italian manufacturing company having a special attention to:

- the importance of metal-replacing materials, such as polypropylene, very strong, light and completely recyclable

- the necessity to separate clean water from rinsing water, a fundamental issue for a professional cleaning

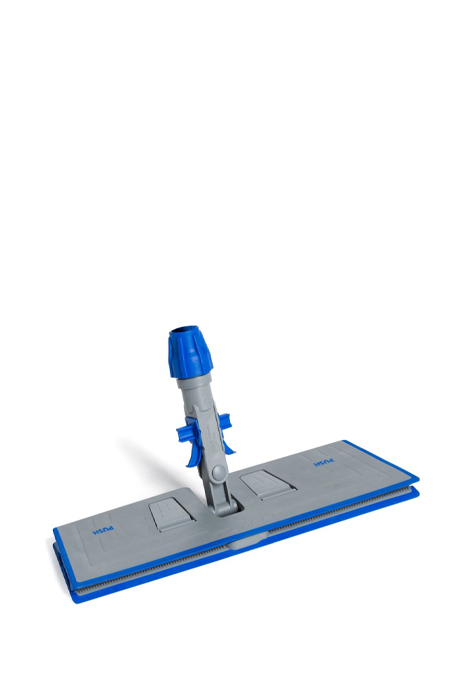

- ergonomic cleaning systems in order to make easier and improve the working conditions of the operators in the cleaning field

This is the basis of a successful business and production policy, that has led to a complete range of products for professional cleaning with more than 4.000 finished items.

YOUR TRUSTED PARTNER

Filmop International is not merely a supplier of cleaning tools, but also a trusted partner totally oriented towards customer’s satisfaction. People choosing Filmop International know they can count on a qualified, available and efficient partner, organized to ship orders promptly with fast and on-time deliveries.

But the added value of the company is without a doubt its great manufacturing flexibility: at every new customer’s request follows an immediate and careful analysis by the R&D department to identify and develop the best possible solution.

Moreover, Filmop International guarantees an excellent pre- and after-sales service, advising its customers on the cleaning system mostly fitting their own needs and supporting them with trainings on site and/or on its premises, with inspections at cleaning yards too.

The right tool for every situation

Filmop provides its customers with different easy-to-use and accessible marketing tools:

- Web site with detailed and constantly updated information

- Freely accessible catalogs and product sheets

- FilmopTalk online magazine with industry articles and interviews

- YouTube channel with videos and tutorials

- Alpha Configurator app to design customized trolleys

- Filmop Academy for product and procedure training

- Showroom for the wide range on offer

WITH AFIDAMP SINCE THE BEGINNING

Filmop is one of the founding fathers and first members of Afidamp, a guarantee body and authoritative point of reference in the cleaning market, which has proudly represented the Italian supply chain since 1981.

Since then, Filmop has been working with Afidamp to contribute to the growth and evolution of the professional cleaning sector, promoting the value and strategic role of a high-quality Made in Italy product.

This collaboration reflects the company's desire to actively participate in the development of a sector that plays a key role in promoting healthy and welcoming environments, protecting the health of the community.

The quality of the products and services offered by the company is guaranteed by the following certifications:

Filmop bases its growth on an organized business system with efficient management, suitable facilities and adequate skills.

Filmop has chosen to implement an environmental management system to control the impacts of its activities on the ecosystem.

Filmop offers a wide range of trolleys, bins and buckets with components made using recycled plastics.

Filmop has obtained for many cloths, mops, flat mops and kentucky mops the eco-label that rewards the best environmentally sustainable products by qualifying them on the market.

.

Filmop has been awarded the Type I environmental label for some Alpha wheeled cabinets, which identifies the best products from a sustainability point of view.

Filmop has obtained the certification of the system for calculating the climate footprint of the trolleys, carried out in accordance with UNI EN ISO 14067:2018.

Its achievements in terms of environment, sustainable procurement, ethics, labour practices and human rights were recognised by EcoVadis, which awarded Filmop the silver medal.

A COSTANT COMMITMENT TOWARDS ENVIRONMENTAL SUSTAINABILITY

Leading company for sustainable development

In an age in which the preservation of our environment is the world top priority, Filmop International is strongly engaged and oriented towards a policy of sustainable development.

Filmop contribution to these important goals finds fulfilment in its engagement:

- to make the most of each person as a human being: the company has a modern and avant-garde structure with wide offices featuring individual booths and working tools, respecting healthcare laws, bright warehouses and industrial machines in compliance with workers’ safety. Moreover, Filmop is strongly committed against the exploitation of minors’ work, has a steady attention to job opportunities to people with disabilities and can boast a staff with long term seniority (15 - 20 years).

- to protect the environment: today, compared to the past time, there are surely the means and knowledge to make conscious choices for environment preservation. Favouring products in compliance with EU laws and manufactured by certified companies can really make the difference.

Filmop and environment preservation

Since the very beginning the company has indeed undertaken a clear path towards eco-sustainability.

Many are the steps that translate the green soul of Filmop International into several concrete and certified results:

- Company and product environmental certifications: ISO 14001, EU ECOLABEL, PSV, CARBON FOOTPRINT SYSTEMATIC APPROACH, ECOVADIS

- Selection of qualified suppliers according to REACH regulation: non-polluting and high-quality raw materials

- Use of certified materials with recycled origin: recycling of raw materials

- Development of products and systems the use of which reduces impact on the ecosystem: 100% recyclable at end-of-life

- Solar energy production thanks to installed photovoltaic systems: use of clean energy, low CO2 emission

- Efficient organization of waste separate collection and leftovers deriving from production processes: reduction of waste production, recovery of materials

- Packaging environmental labelling: clear and immediate information on the material and the correct disposal of each part of the packaging

READ MORE >

AT THE FOREFRONT OF ENVIRONMENT OFFERING PRODUCTS AND CLEANING SYSTEMS IN COMPLIANCE WITH CAM CRITERIA

What are CAMS?

CAM are Minimum Environmental Criteria identified in certain product categories and defined in the relevant Ministerial Decrees as a concrete application of PANGPP, the National Action Plan, with which Italy aligns itself to the environmental directives issued by the European Union (GPP - Green Public Procurement).

The CAM application is compulsory: to choose ecofriendly solutions is a responsability and a common duty for environmental protection. In the Cleaning field there are two relevant CAM:

The requirements in CAM are divided into:

- Technical specifications: mandatory characteristics that make work, services and supplies COMPLIANT WITH MINISTERIAL REGULATIONS

- Contractual clauses: mandatory minimum requirements that make products and services COMPLIANT WITH MINISTERIAL REGULATIONS

- Rewarding criteria: aspects of interest from an environmental point of view that MAY INCREASE THE SCORE in the bidding process

Filmop has realized a wide range of products and systems in line with what is indicated in the relevant CAM.

SUPPORTING THE AIRC FOUNDATION FOR CANCER RESEARCH

Filmop firmly believes in the value of research. This is why it concretely supports the AIRC Foundation and paediatric cancer research, renewing its contribution year after year.